Food Process Machine Steel Forging Parts

Maple machinery continuously invests in the development of our people, processes and machines in order to achieve our development objectives. Investment and innovation have ensured the standard of Food Process Machine Steel Forging Parts. Due to the continuous internal development and our pursuit of perfection, we have been recognized by customers.

Send Inquiry

When steel is heated to forging temperature, it becomes ductile and malleable, and is molded into the shape we choose by applying pressure. With proper processing methods, steel forging can make the Food Process Machine permanently formed without cracking, due to its plasticity. Forging steel requires an induction heating system, a forging furnace, or a forging furnace to heat the steel to a sufficient temperature. Thermal cycling and deformation processes are the main causes of recrystallization and grain refinement in metallurgy. This reinforces the resulting Food Process Machine Steel Forging Parts, particularly in terms of shocks

Product Parameter (Specification)

|

Item |

Food Process Machine Steel Forging Parts |

Roughness |

Ra 1.6 |

|

Tolerance |

±0.01mm |

Material |

Alloy Steel |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-60KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Closed Die Forging |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

Maple’s Services for Food Process Machine

Since the establishment of the company, Maple machinery Castings has specialized from day one in the production of high quality and sophisticated Food Process Machine Steel Forging Parts for Food Process Machine. At Maple machinery, we offer our customers a complete solution for Steel Forging Parts. In our organization, we perform each sub-process associated with the production of complex Steel Forging Parts. This guarantees a complete in-house solution where customers benefit from the superior quality and reliability they have a right to expect from their Steel Forging Parts supplier..

Supporting Service for Food Process Machine parts

◉ As mentioned above, in order to work in adverse conditions, the performance of the Food Process Machine Steel Forging Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc.

◉ Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment

◉ Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment.

◉ Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion…

◉ Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts.

Common Material for Agricultural Machinery

We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Food Process Machine Steel Forging Parts :

Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45…

Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo…

Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20…

Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300…

Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2…

High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr…

Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360…

High Manganese steel: X120Mn12, Mn12, Mn13…

The Parts We Supplying for the Food Process Machine

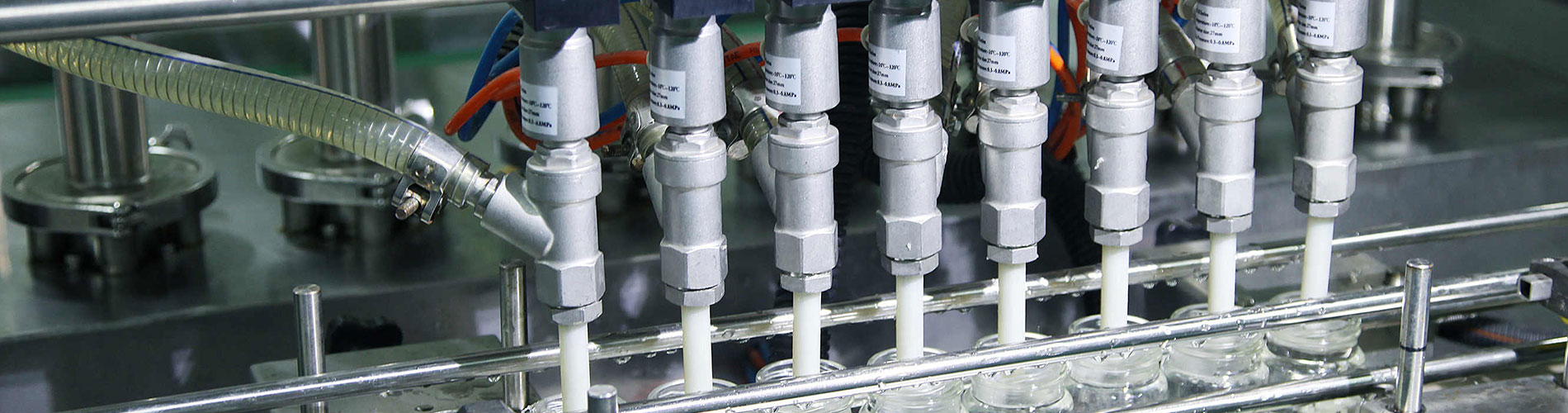

We have manufactured a wide range of Food Process Machine Steel Forging Parts. The following are typical products:Valve joint, Ball valve body, Gate valve body, Choke valve body, Beer valve body,Purification water brass,Hybrid valve, ....

Why Closed Die Forging

Compared with casting, forging has its special advantages:

1. In the case of the same material, the mechanical properties of forgings are better than those of castings.

2. The forgings strength is higher and the fatigue resistance is stronger.

3. The forgings has better compactness.

4. There are no internal defects and surface defects.

5. Fast production speed, high efficiency, suitable for mass production of products.

6. The product quality is stable.