Hydraulic System Steel Investment Casting Parts

Maple is a key player in the process industry in the field of precision investment casting. Maple has developed many Hydraulic System Steel Investment Casting Parts, which are usually cast into special alloys. These special alloys are used because components usually work in environments that are corrosive (harsh), have large temperature differences, or require very hard, strong, or light products.

Send Inquiry

Hydraulic System Steel Investment Casting Parts

1.Product Introduction

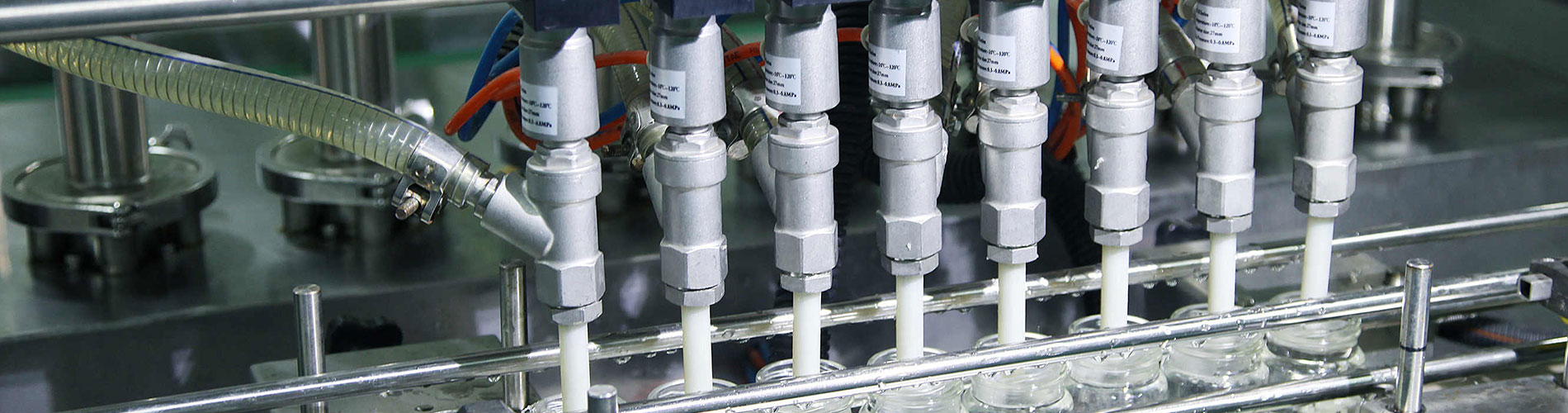

The hydraulic system uses fluid to drive tools, especially those that perform continuous and repetitive tasks, as well as to move, position and lift heavy objects, such as machine components and raw materials. Hydraulic system is the basic element of manufacturing, construction equipment, construction infrastructure and vehicles. Hydraulic System Steel Investment Casting Parts can meet the complex design of hydraulic system to complete the specific motion trajectory involved.

2.Product Parameter (Specification)

|

Item |

Hydraulic System Steel Investment Casting Parts |

Roughness |

Ra 1.6 |

|

Tolerance |

±0.01mm |

Material |

Casting Steel |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-2000KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Investment Casting |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

3. Maple’s Service for HydraulicCylinder System

◉ Today, Maple Machinery caters to different customers of hydraulic industry with premium machined parts, forgings, and castings. These parts include Lug Bases, Rod Clevises, Bearing, Heads, Top Nut, Glands, Pistons and Gears. Our customers rely on us because of our professional customer care and high-precision machined components. Most of these parts carry with tensile strength.

◉ Maple has over ten years of experience in manufacturing hydraulic parts, we can forge small parts and larger parts weighing hundreds of kilograms. We understand our customer needs and also offer pressure testing, NDT, and other services.

4.Supporting Service for HydraulicCylinder System Components

◉ As mentioned above, in order to work in adverse conditions, the performance of the Hydraulic System Steel Investment Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc.

◉ Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment

◉ Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment.

◉ Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion…

◉ Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts.

◉ Common Material for Hydraulic System

We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Hydraulic System Steel Investment Casting Parts:

Carbon Steel:1015,1020,1035,1045,20Mn,25Mn,A570.GrA, SJ355, C45…

Alloy Steel:4130,4135,4140,4340,8620,8640,20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo…

Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20…

Gray Iron:GG-15,GG-20,GG-25,Class 20B,Class 25B,Class 30B, GJL-250, GJL-300…

Ductile Iron:GGG-40,GGG-50,60-40-18,65-45-12,70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2…

High Chromium cast iron:15%Cr-Mo-HC,20%Cr-Mo-LC,25%Cr…

Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356,A360…

High Manganese steel: X120Mn12, Mn12, Mn13…

5.The Parts We Supplying for The HydraulicCylinder System

We have manufactured a wide range of Hydraulic System Steel Investment Casting Parts. The following are typical products:

Lug Bases, Rod Clevises, Bearing, Heads, Top Nut, Glands, Pistons and Gears

6.Why Investment Casting

◉ Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military.

◉ As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.