Off Highway Industry Grey Iron Casting Parts

Maple machinery's cooperation with Off Highway Industry Grey Iron Casting Parts customers is our greatest asset. As a team with a passion for Grey Iron casting products, we do everything possible to meet our customers' expectations. Add value, with the best cost performance Off Highway Industry Grey Iron Casting Parts, coupled with a reliable supply chain casting the highest quality products

Send Inquiry

Cast iron mixed with layered graphite is called gray cast iron. These contain more than 2% carbon and are supplemented with other elements such as silicon and manganese. Compared with steel castings, grey cast iron has lower energy consumption during melting, and has good castability and shock absorption characteristics. For gray cast iron, carbon is used in the form of sheet graphite, unlike ductile iron, where carbon is used in the form of ductile graphite. Grey cast Iron is used in many Off Highway Industry Grey Iron Casting Parts because of its good castability.

Product Parameter (Specification)

|

Item |

Off Highway Industry Grey Iron Casting Parts |

Roughness |

Ra 1.6 |

|

Tolerance |

±0.01mm |

Material |

Casting Steel/Casting Iron |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-5000KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Sand Casting |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

Maple’s Services for Off Highway Industry

Maple Machinery has been working with some of the most prominent Off Highway industries. We meet the requirements of customers and complete the standard Off Highway Industry Grey Iron Casting Parts according to the drawings. We make all our products carefully. Taking into account the wear nature of heavy transport, we improve the quality of our transport. I hope that when customers receive the products, the products are perfect and satisfactory.

Supporting Service for Off Highway Industry parts

◉ As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Grey Iron Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc.

◉ Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment

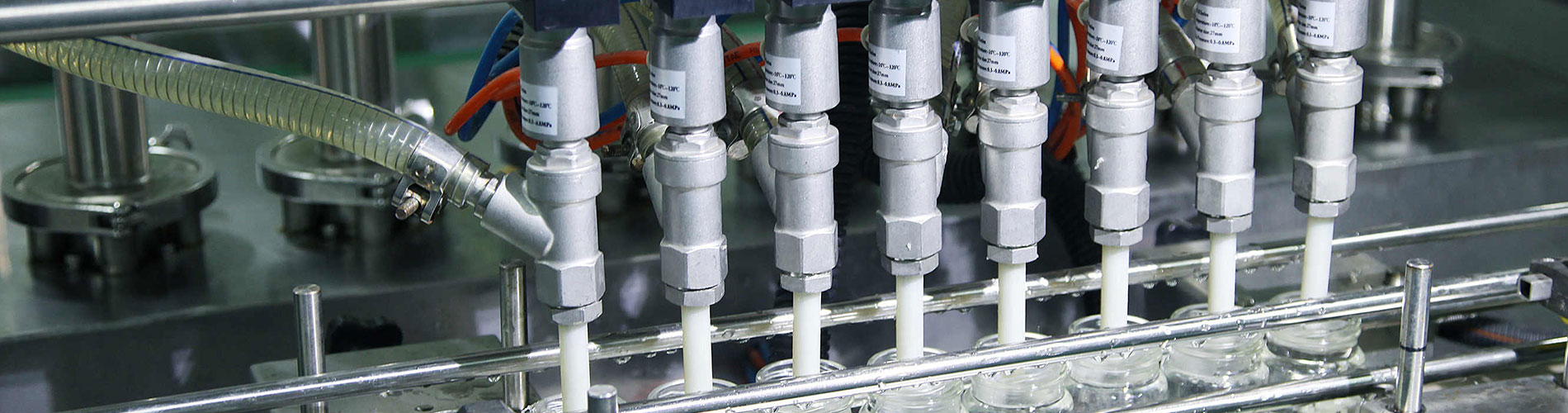

◉ Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment.

◉ Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion…

◉ Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts.

Common Material for Off Highway Industry parts

We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Grey Iron Casting Parts:

Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45…

Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo…

Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20…

Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300…

Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2…

High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr…

Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360…

High Manganese steel: X120Mn12, Mn12, Mn13…

The Parts We Supplying for the Off Highway Industry

We have manufactured a wide range of Off Highway Industry Grey Iron Casting Parts. The following are typical products:Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar.

Why Sand Casting

Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt.

Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.