Construction Machinery Steel Forging Parts

Closed die forging is Maple machinery’s second largest business scope and makes our company an expert in metal manufacturing solutions. We are committed to provide customers with a full range of professional manufacturing services, and the strictest quality control. No matter the Construction Machinery Steel Forging Partscomes from ourforger other manufacturers, we will finish the machining and quality inspection in our own machine shop to ensure that the parts delivered to customers are 100% perfect. We not only help customers purchase raw Construction Machinery Steel Forging Parts, but also finish machining and treatment in our own machine shop; we can also improve the design of casting or welding parts into forging parts, and help customers provide process solutions to obtain forgings with stronger mechanical properties and more stable quality.

Send Inquiry

Construction Machinery Steel Forging Parts

1.Product Introduction

In Construction Industry, most parts need higher strength and wear resistance. Compared with castings, forgings have higher density and strength. For the same products, the parts produced by forging have longer service life, higher strength and more reliability. On the premise that it can be used, we will more recommend customers to use Construction Machinery Steel Forging Parts.

2.Product Parameter (Specification)

|

Item |

Construction Machinery Steel Forging Parts |

Roughness |

Ra 1.6 |

|

Tolerance |

±0.01mm |

Material |

Alloy Steel |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-60KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Closed Die Forging |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

3. Maple’s Service for Construction Industry

◉ Construction machinery is essential for building purposes and involves loading and unloading of equipment and materials. We use these machineries for road maintenance, landfill, material transportation, and other tasks related to the construction industry. Some widely used machinery and equipment in construction machinery includes trenchers, drills, shovels, excavators, and road rollers. Our customers rely on us to make the most durable and reliable construction machinery.

◉ Our customers choose us over others for their needs for construction machinery because of our high-quality products and competitive costs. We customize our services to meet customer needs and earn high satisfaction because of the advanced technology and extensive after-sales support.

◉ MapleMachinery has been offering professional Construction Machinery Steel Forging Partsservices to our customers for many years now. They rely on us completely because of our professional services and excellent technology and advanced equipment. We can also improve the original forgings, and customers provide process solutions and purchase blanks. It is because of our high-end expertise and in-depth cooperation; we have exported millions of US dollars’ worth of forgings.

4.Supporting Service for Construction Components

◉ As mentioned above, in order to work in adverse conditions, the performance of the Construction Machinery Steel Forging Partsmust be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc.

◉ Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment

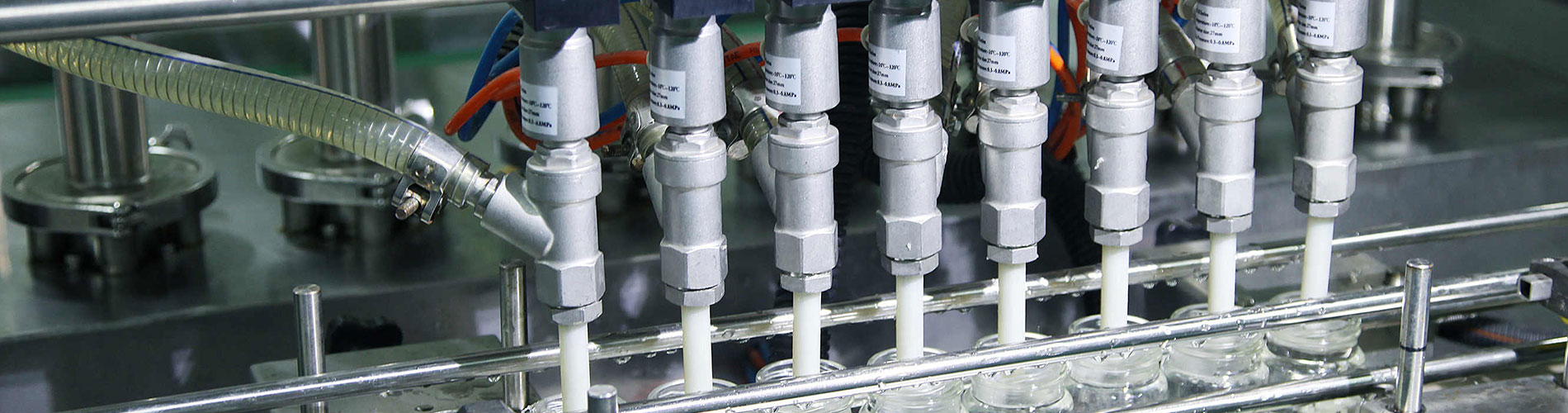

◉ Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment.

◉ Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion…

◉ Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts.

◉ Common Material for Construction Industry

We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Construction Machinery Steel Forging Parts:

Carbon Steel:1015,1020,1035,1045,20Mn,25Mn,A570.GrA, SJ355, C45…

Alloy Steel:4130,4135,4140,4340,8620,8640,20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo…

Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20…

Gray Iron:GG-15,GG-20,GG-25,Class 20B,Class 25B,Class 30B, GJL-250, GJL-300…

Ductile Iron:GGG-40,GGG-50,60-40-18,65-45-12,70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2…

High Chromium cast iron:15%Cr-Mo-HC,20%Cr-Mo-LC,25%Cr…

Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356,A360…

High Manganese steel: X120Mn12, Mn12, Mn13…

5.The Parts We Supplying for The Construction Industry

We have manufactured a wide range of Construction Machinery Steel Forging Parts. The following are typical products:

Grate Bar, Burner, Dump Block, Y-Links, Spreader bar, Sockets, Roller lever, Bushing, Pallet, Crusher components, Hammer, Bucket teeth, Sleeves, Impeller, Gear cases, Chain Links, Adapters, Shackle.

6. Why Closed Die Forging

Compared with casting, forging has its special advantages:

1. In the case of the same material, the mechanical properties of forgings are better than those of castings.

2. The forgings strength is higher and the fatigue resistance is stronger.

3. The forgings has better compactness.

4. There are no internal defects and surface defects.

5. Fast production speed, high efficiency, suitable for mass production of products.

6. The product quality is stable.