Industry News

Maple in improved Quality of Cold Forged Shafts

MAPLE is a quality driven company.1, by a quality policy which is clearly communicated inside Maple to all employees as well as by excellent quality KPIs. It is also documented by continuously rising the state of the art in quality technology which is applied in Maple production.

Read MoreForged hub

First, Maple explains that the manufacturing process for cast and forged wheels is different. Casting is the process of melting metal into a liquid that meets certain requirements and then pouring it into a casting tool. After cooling, solidification and cleaning, the casting basically has a predete......

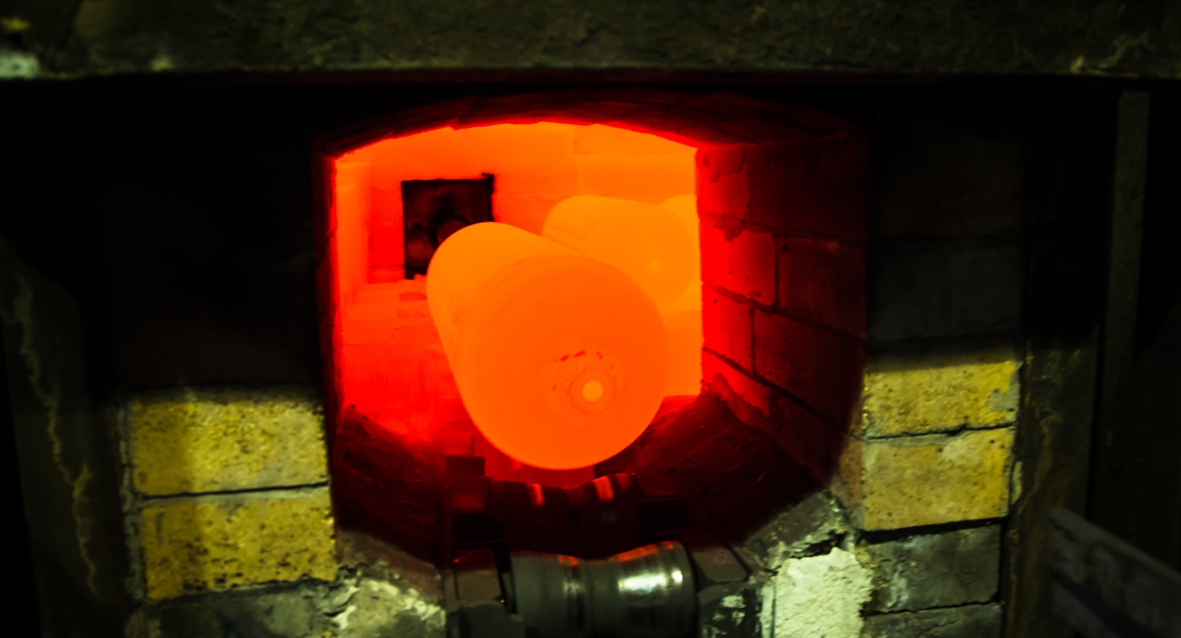

Read MoreDefinition of forging and die casting

Conventional glass surface VS ETFE surface The definition of forging and die casting can be summarized as follows: - Forging: Using forging hammer, press or hydraulic equipment to change the volume, shape, internal organization and mechanical properties of metal materials;

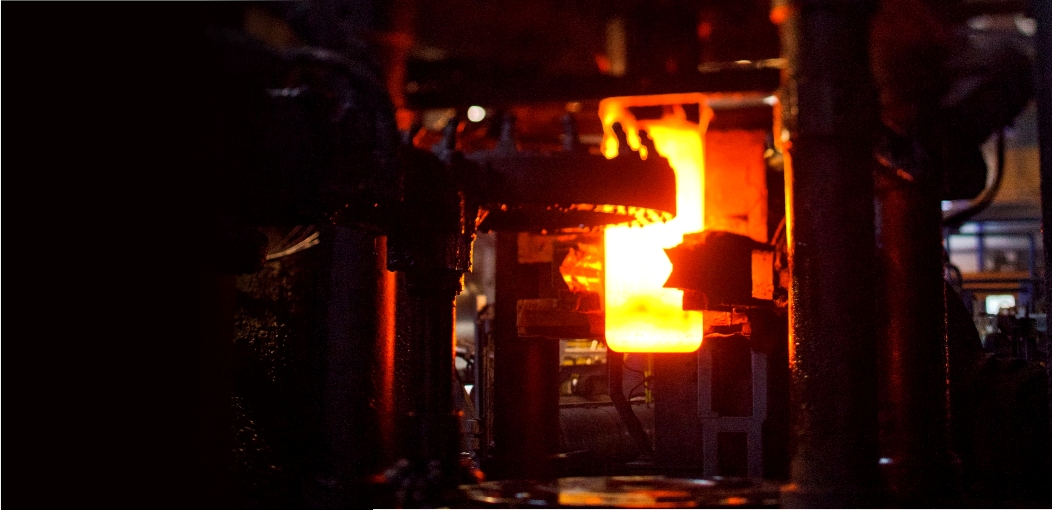

Read MoreLarge forgings

Large forgings in Maple are mostly used for key components of large machinery, and due to the harsh working environment and complex forces, the quality requirements for large forgings in the production process are very high. Large forgings are forged directly from ingot. In the production of large f......

Read MoreBenefits of Forgings and Advantages of drop forging

During the rolling of the starting material or during the drop forging itself, defects such as pores and blowholes, which often occur in the production of cast parts, are closed. As a result, forged parts are more stable than cast parts with the same or even lower weight. Compared to machined compo......

Read More