Off Highway Industry Steel Investment Casting Parts

Maple Machinery leverages advanced technology and extensive expertise to meticulously craft top-tier products. Our precision castings play a pivotal role in high-speed rail systems globally. Collaborating with prominent railway parts manufacturers worldwide, we ensure the seamless integration of our Off-Highway Industry Steel Investment Casting Parts. Clients entrust our products with confidence, given our stringent quality control measures. We affirm the dependability of the steel castings and forgings we produce for the Off-Highway Industry, upholding unwavering standards of reliability.

Send Inquiry

Off Highway Industry Steel Investment Casting Parts

1.Product Introduction

◉ Within the off-highway sector, sustaining uninterrupted equipment operation amid unpredictable and challenging conditions necessitates the incorporation of robust, enduring, and dependable mechanical components by manufacturers. This ensures the persistent and high-performance functionality of the utilized machinery.

◉ Situated in Ningbo, our company holds ISO 9001:2015 certification, underscoring our commitment to producing top-notch Off-Highway Industry Steel Investment Casting Parts. Through collaborative partnerships with off-highway industry clients, our steel and alloy forgings consistently adhere to industry benchmarks for strength and durability.

2.Product Parameter (Specification)

|

Item |

Off Highway Industry Steel Investment Casting Parts |

Roughness |

Ra 1.6 |

|

Tolerance |

±0.01mm |

Material |

Casting Steel |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-80KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Investment Casting |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

3. Maple’s Servicesfor Off Highway Industry

◉ Maple Machinery expands its manufacturing service footprint with a strategic entry into the Off-Highway Industry. Our enduring partnerships with industry leaders underscore our pride, as our products and sales consistently lead the market. Embracing continuous improvement, we persistently challenge ourselves to maintain a competitive edge. Our repertoire includes the production of Off-Highway Industry Steel Investment Casting Parts such as Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hubs, Base plates, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clips, and Joint bars.

◉ The railway sector forms a critical nexus for transportation and distribution, demanding cost-effective and durable equipment across diverse applications. From freight to passenger services, railways rely on different castings for various functionalities. Maple Machinery, drawing from extensive experience, specializes in crafting precise, robust, and enduring steel and iron castings in varied sizes, shapes, and materials. Our manufacturing prowess extends to a broad spectrum of castings and forgings tailored for railway infrastructure and transportation equipment.

4.Supporting Service for Off Highway Industry parts

◉ As previously highlighted, achieving exceptional performance in adverse conditions necessitates more than the production of raw castings or forgings for Off-Highway Industry Steel Investment Casting Parts. It demands additional processes such as heat treatment, machining, surface treatment, and NDT testing.

◉ Heat Treatment: A pivotal step to enhance mechanical properties, heat treatment is tailored to the strength requirements of each part. This process improves critical attributes such as hardness, yield strength, tensile strength, and elongation.

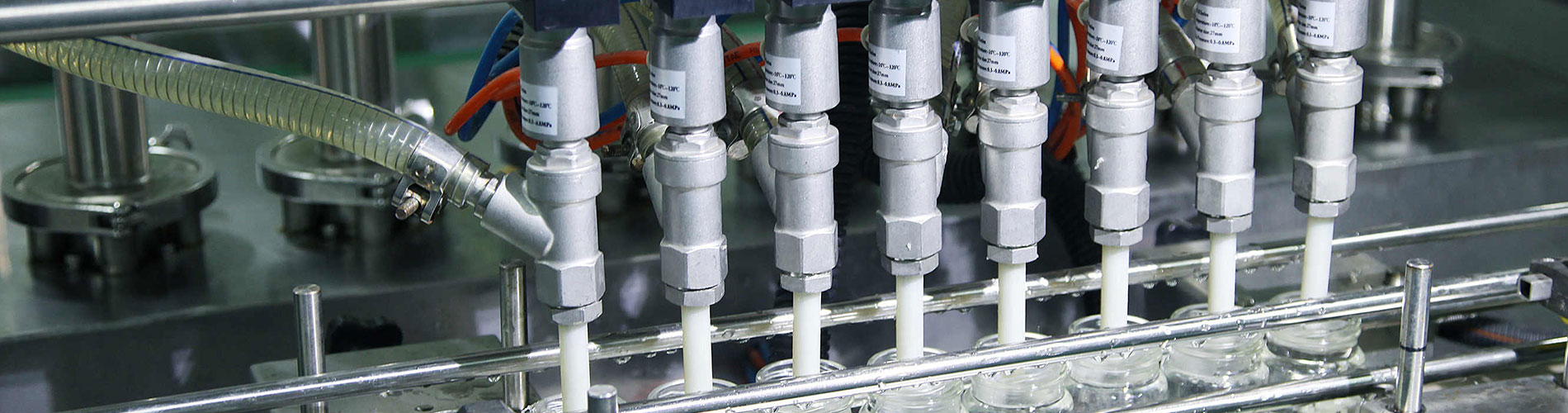

◉ Machining: Our in-house machine shop equipped with advanced machinery allows us to fulfill a comprehensive range of machining requirements efficiently.

◉ Surface Treatment: Crucial for ensuring optimal performance in challenging environments, surface treatments serve various purposes. Zinc plating prevents rust, nickel plating enhances wear and corrosion resistance, while phosphating guards against corrosion.

◉ Non-Destructive Testing (NDT): Serving as the final and paramount step, NDT is conducted meticulously to confirm the absence of surface defects (e.g., cracks, sand holes, blow holes) and internal defects (such as shrinkage and slag) in the delivered parts.

◉ Common Materials for Off-Highway Industry Parts:

We possess the capability to manufacture parts using standard and special materials. The following list comprises our commonly utilized materials for manufacturing Off-Highway Industry Steel Investment Casting Parts:

Carbon Steel: Our repertoire includes a range of carbon steel materials, ensuring versatility and strength for Off-Highway Industry Steel Investment Casting Parts. Some common carbon steel grades we work with are 1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45...

Alloy Steel:We specialize in the production of Off-Highway Industry parts using alloy steel to meet demanding performance requirements. Our alloy steel options encompass grades such as 4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo...

Stainless Steel: Ensuring corrosion resistance and durability, our stainless steel materials meet the high standards of the Off-Highway Industry. We work with stainless steel grades including 304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20...

Gray Iron:For applications demanding robust and stable components, we offer a selection of gray iron materials, such as GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300...

Ductile Iron: Catering to diverse strength requirements, our ductile iron materials include GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06, QT500-7, QT400-18, QT700-2...

High Chromium Cast Iron: For specialized applications demanding high wear resistance, we provide high chromium cast iron materials, such as 15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr...

Aluminum: Offering lightweight solutions without compromising on strength, our aluminum materials include AlSi7Mg, AlSi12, AlSi10Mg, A356, A360...

High Manganese Steel:Meeting the demands of high-wear applications, our high manganese steel options include X120Mn12, Mn12, Mn13...

5.The Parts We Supplying for the Off Highway Industry

We have manufactured a wide range of Off Highway Industry Steel Investment Casting Parts. The following are typical products:

Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar.

6.Why Investment Casting

◉ Investment casting stands out as a premier process for crafting high-quality castings and molding metal alloys. This method is particularly advantageous for casting metals with elevated melting points and producing intricately designed parts, a critical need in industries like aviation, automotive, and defense.

◉ As a seasoned investment casting manufacturer, our specialized techniques are widely employed to yield castings that are not only heavier and stronger but also boast complex shapes. Partnering with us offers a myriad of advantages, including cost-effectiveness, a more economical molding process for intricate designs, and heightened precision. An additional competitive edge held by Maple Machinery lies in its prominent position as a leader in casting technology within China. We are committed to delivering precision castings and micron-level processing services to meet the exacting standards of our clients.