Steel Casting

Your Reliable Steel Casting Supplier & Manufacturer in China

Are you looking for a steel casting supplier & manufacturer in China?

You come to the right place. Maple Casting will be one of your reliable steel casting suppliers in China. We are a leading steel casting manufacturer and CNC machining service provider. We have a steel casting factory cooperator, that provides steel casting parts for us and Maple casting will make machining for these cast steel casting parts.

Steel Casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the steel casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military.

As professional steel casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for steel casting. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

- View as

Agricultural Machinery Stainless Steel Casting Parts

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

Read MoreSend InquiryHydraulic System Steel Lost Wax Casting Parts

Maple machinery invests in modern and sophisticated equipment to meet all customer requirements for Hydraulic System Steel Lost Wax Casting Parts in terms of reliability, repeatability and flexibility. Maple machinery has extensive experience in lost wax casting and industrial certifications which are updated and improved every time.

Read MoreSend InquiryMarine Steel Lost Wax Casting Parts

Maple machinery's infrastructure is further divided into sub-divisions, such as manufacturing, Quality testing, Sales and Marketing, etc., to ensure smooth business processes. Our production units are equipped with the latest equipment and modern technology to carry out a smooth production process. The skilled and experienced staff on our team are familiar with the equipment and machinery installed, enabling us to manufacture the very best quality Marine Steel Lost Wax Casting Parts.

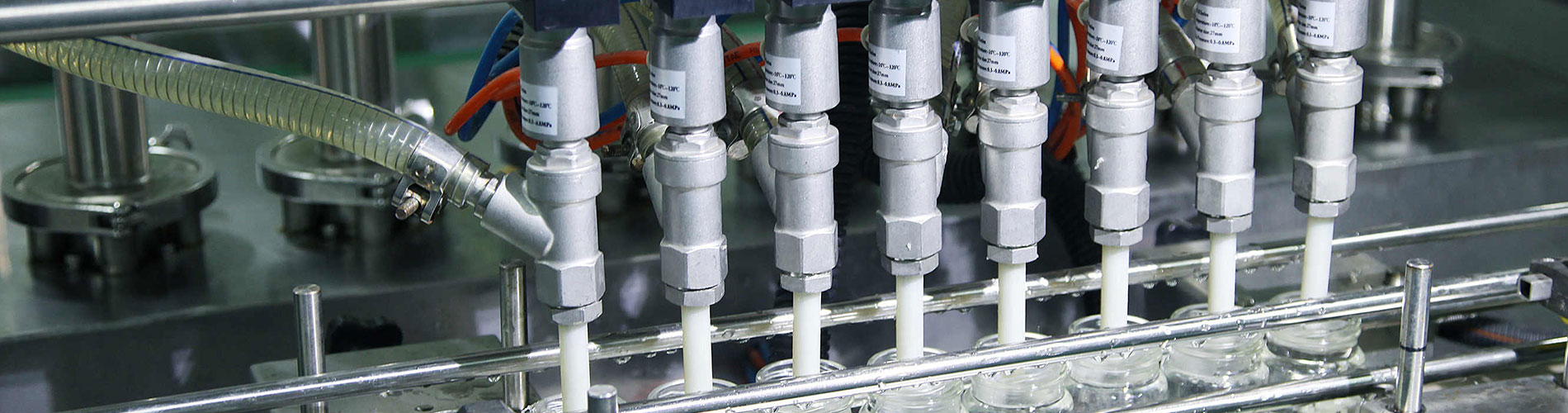

Read MoreSend InquiryFood Process Machine Steel Lost Wax Casting Parts

Maple machinery is an international metals manufacturer that has been developing alloys and processes for high performance cast components for food machinery, oil and gas, windmills and hydraulics, steel and more for many years. Maple machinery has earned a global industrial reputation for meeting customer requirements through its well-known solid technical expertise. Maple machinery's strategy is to provide its customers with high quality Food Process Machine Steel Lost Wax Casting Parts through a performance culture based on innovation, reliability and environmental protection.

Read MoreSend InquiryValve Steel Lost Wax Casting Parts

Maple machinery's sophisticated technical expertise and experience inspire and motivate us to enter the field of precision Precision Castings we manufacture Valve Steel Lost Wax Casting Parts to perfection. We are a team of qualified and experienced metallurgical and mechanical engineers. Our factory is located in Ningbo, China. In order to make our products perfect, we have installed the most advanced equipment and machines. We have also set up our own laboratory, equipped with the latest instruments to ensure ultra-smooth finish, dimensional accuracy and required hardness, and to determine precise metal percentages.

Read MoreSend InquiryHeavy Industry Steel Lost Wax Casting Parts

Through a robust quality management system, uncompromising adherence to established standards, a relentless focus on precision, and the constant pursuit of improvement and customer satisfaction - these are all elements that help us deliver the highest quality Heavy Industry Steel Lost Wax Casting Parts to our customers worldwide.

Read MoreSend Inquiry