Heavy Industry Stainless Steel Casting Parts

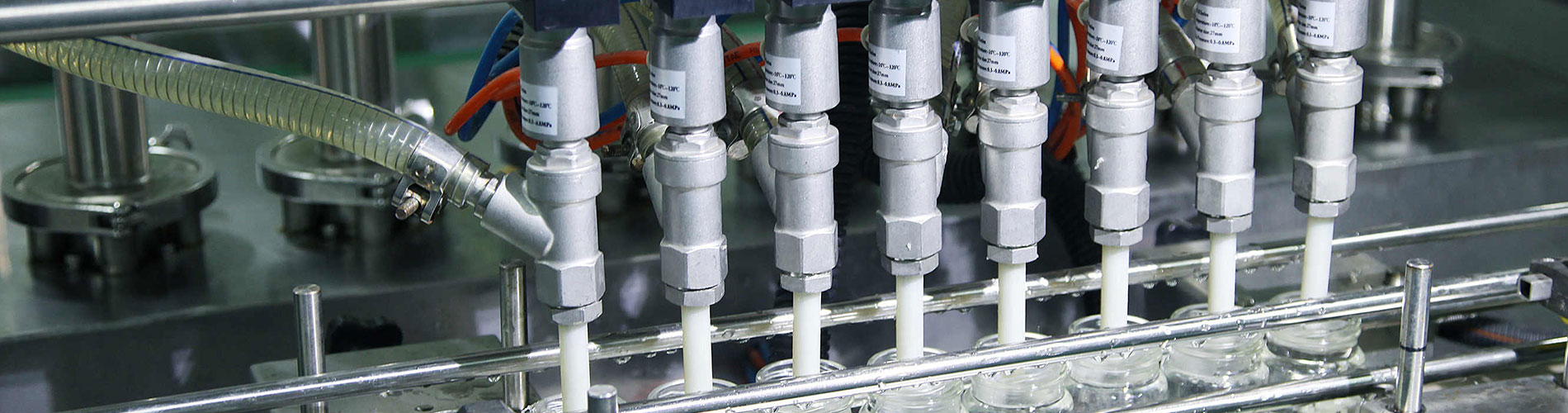

Maple machinery is an advanced manufacturer of Heavy Industry Stainless Steel Casting Parts in China with satisfied customers around the world and a well-established reputation in the foundry industry. He has nearly 20 years of manufacturing experience in the Stainless Steel field. Maple machinery in particular is able to offer sophisticated stainless steel casting products.

Send Inquiry

Our Heavy Industry Stainless Steel Casting Parts are under tremendous pressure, shocks, etc., which makes us strive every day to innovate and make durable products for the industry. In addition, at Maple machinery, we can also provide our customers with sub-assembly of components, processing of large parts and other high value added services.

Product Parameter (Specification)

|

Item |

Roughness |

Ra 1.6 |

|

|

Tolerance |

±0.01mm |

Material |

Casting Steel |

|

Certification |

ISO 9001:2015 |

Weight |

0.01-2000KG |

|

Machining |

CNC |

Heat Treatment |

Quenching & Tempering |

|

Inspection |

MT/UT/X-Ray |

Lead Time |

30 Days |

|

Package |

Plywood Case |

Method |

Investment Casting |

|

Capacity |

50000 Pcs / Month |

Origin |

Ningbo, China |

Maple’s Service for Heavy Industry

In the field of Heavy Industry, we offer a variety of stainless steel solutions for the growing demand. , numerous Parts of all weights and shapes form part of our Heavy Industry Stainless Steel Casting Parts range. Based on our years of experience in this field, we adapt our approach to each new project and are more than happy to advise you on the initial design of components.

Supporting Service for Heavy Industry Components

◉ As mentioned above, in order to work in adverse conditions, the performance of the Heavy Industry Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc.

◉ Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment

◉ Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment.

◉ Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion…

◉ Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts.

Common Material for Heavy Industry

We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Heavy Industry Stainless Steel Casting Parts:

Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45…

Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo…

Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20…

Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300…

Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2…

High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr…

Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360…

High Manganese steel: X120Mn12, Mn12, Mn13…

The Parts We Supplying for The Heavy Industry

We have manufactured a wide range ofHeavy Industry Steel Lost Wax Casting Parts. The following are typical products:

Wire rope grip, Door handle, beam clamp for construction, spider bracket, Car parts, Sockets, Roller lever, Bushing, Pallet, Crusher components, Hammer, Bucket teeth, Sleeves, Impeller, Gear cases, Chain Links, Adapters, Shackle.

Why Investment Casting

Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military.

As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.