Call Us

+86-19858305627

Email Us

sales@maple-machinery.com

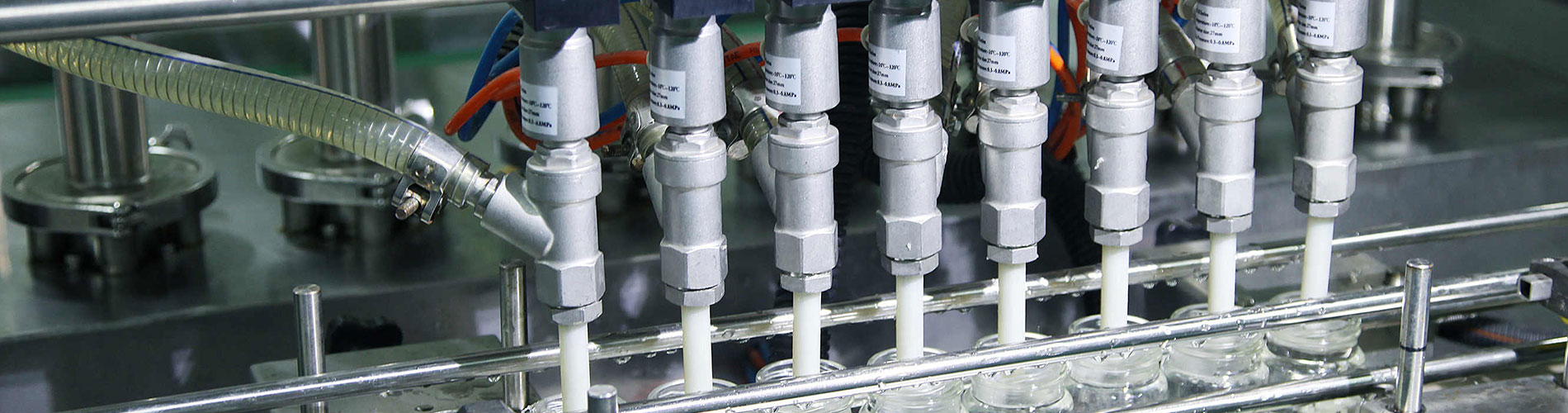

Food processing equipment steel investment castings Manufacturers

Our factory provides sand casting, closed die forging, open die forging,etc. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. We take high quality, reasonable price and perfect service.

Hot Products

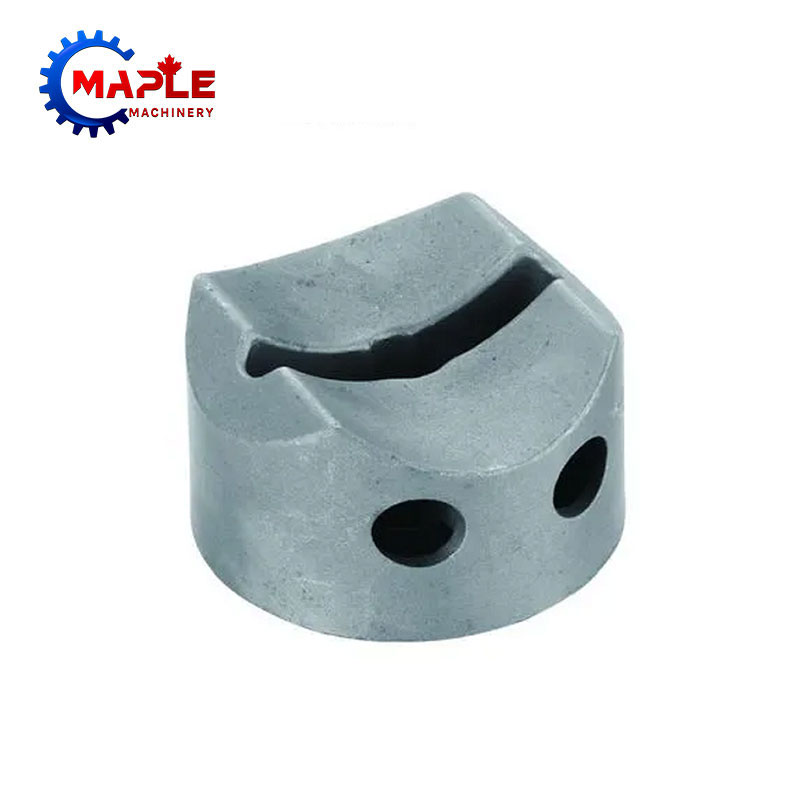

Heavy Industry Ductile Iron Casting Parts

Located in Ningbo, China, close to the port has its own production plant, as well as an engineering team dedicated to providing customers with solutions to work with quality and the latest technology. It serves the whole world. Thanks to our expertise, our modern machinery and high quality production technology the production stage delivers the right quantity of high quality Heavy Industry Ductile Iron Casting Parts..Cast Iron Hydraulic Manifolds

Maple Machinery stands as a trusted international ally in the realm of Cast Iron Hydraulic Manifolds. Our offerings find extensive application across diverse industries such as automotive, chemical, construction, and mining. What sets us apart is our all-encompassing service approach. We not only specialize in casting production but also excel in machining and heat treatment, significantly streamlining the order fulfillment process and ensuring prompt delivery. This comprehensive service model underscores our commitment to efficiency and client satisfaction.Heavy Industry Grey Iron Casting Parts

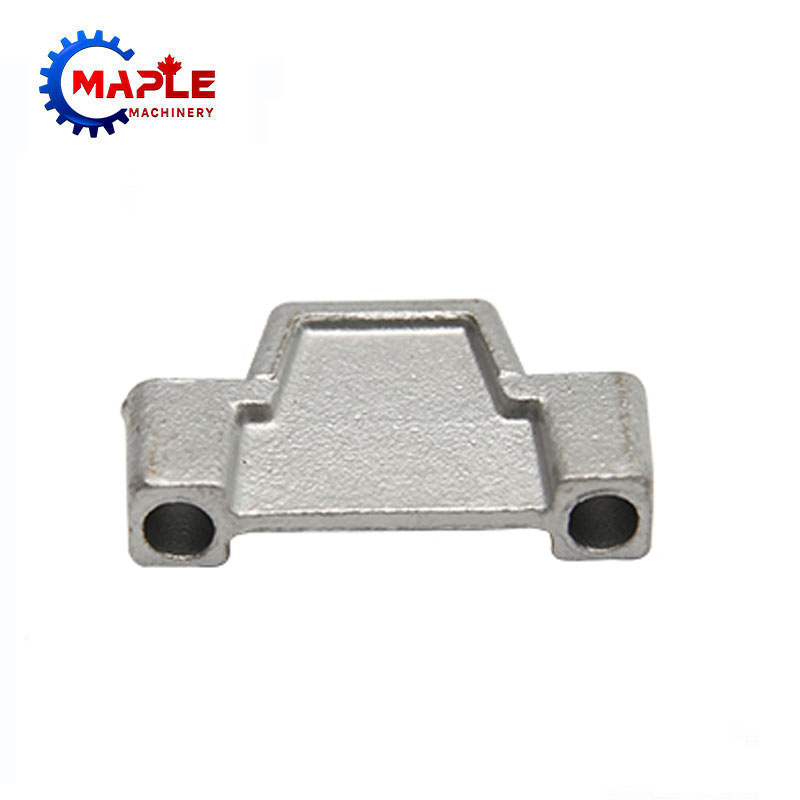

Maple machinery is a manufacturer of Heavy Industry Grey Iron Casting Parts, specializing in the production of different types of castings. Each member firm has its own specific knowledge and production technology. All foundries have their own independent activities. The company makes custom-made Iron Sand Casting Parts for global customersHydraulic System Stainless Steel Forging Parts

Maple machinery is a proud Chinese manufacturer offering forging solutions for over 15 years. Our skilled staff has been producing high quality stainless steel forgings, building a strong reputation as a market leader, working with customers worldwide. We understand our customers' demand for Hydraulic System Stainless Steel Forging Parts and pressure for quick turnaround. We work with Hydraulic System customers to control costs while maintaining the high manufacturing, quality and logistics standards they require. We offer a complete service including design, tooling and tool makingValve Iron Sand Casting Parts

With over 15 years of expertise, Maple Machinery has been a stalwart in the production of Valve Iron Sand Casting Parts, operating as a prominent metal manufacturer situated in Ningbo, China. The foundation of our company was laid with the vision of establishing a firm with a strong technical and metallurgical background in metal and metal parts manufacturing. Over the past 15 years, we take pride in our effective service to a global clientele. Throughout this journey, we have harnessed our wealth of experience and technical proficiency to cater to the diverse requirements of our esteemed customers in the United States, Canada, and across North America. Our commitment to quality and customer satisfaction has been a driving force in our success, and we look forward to continuing to meet and exceed the expectations of our clients.Construction Machinery Steel Lost Wax Casting Parts

All Construction Machinery Steel Lost Wax Casting Parts of Maple machinery are manufactured with internal strength and integrity. Through a sophisticated Lost Wax Casting process, we can produce parts with strict tolerances. Maple machinery uses solidification modeling software to predict the internal quality level of castings before parts are manufactured, greatly reducing time to market and development costs through a "trial and error" approach to process development.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy